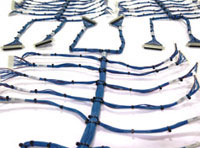

Harnesses & Cabling Overview

Advanced Design and Manufacturing has extensive experience in manufacturing of application specific wire harnesses, cables and assemblies. In the electrical harnessing work cells, ADM takes pride in retaining highly trained Technicians who receive continuous top-level training from ADM's Certified IPC Trainers. Each Technician learns to master the technique of running, tying, terminating and labeling harness assemblies. Automated wire processing and crimping equipment allows ADM to build very complex harnesses at reduced lead-times.

— Director of Engineering, GT Advanced Technologies

The Engineering team at Advanced Design and Manufacturing will assist in the design and cost savings opportunities for your specific projects. ADM offers harness design services to include: wire harness assembly drawings, wire run lists, as well as bill of material generation.

To ensure the highest level of quality, in-process production inspections are performed during various stages of the assembly process. A final inspection includes a 100% continuity test on the Weetech continuity analyzer and if needed a Hi-Pot test is also performed.

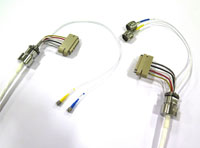

Manufacturing Harnesses and Cable Assemblies

ADM specializes in manufacturing harnesses and cable assemblies, including:

- Control Harnesses

- Gas & Fluid Harnesses

- Internal Box Harnesses

- High Voltage

- Conduit Assemblies

- Interconnect Cable Assemblies

- Motor Control

- Cable Assemblies

Industries ADM Serves

Homeland Security

Fluid Management

Food Service

Medical/Life Science

Military

Nanotechnology

Optics

Petroleum

Pulp & Paper

Roadway Infrastructure

Safety

Semiconductor

Scientific Research

Test/Instrumentation